VetroMount® Floor profile F

Please note:

Test reports, country-specific certificates and further information available in the “Downloads” section.

Technical Data

| Mounting | top mounting |

| Material | aluminium |

| Finish | E6/C0 |

| Line | VetroMount® |

| Product type | Floor profile |

| Rail load | 1.0 kN (UK: 0.74 kN) |

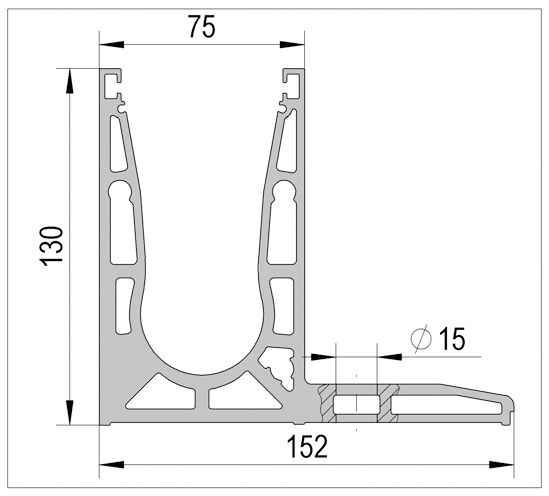

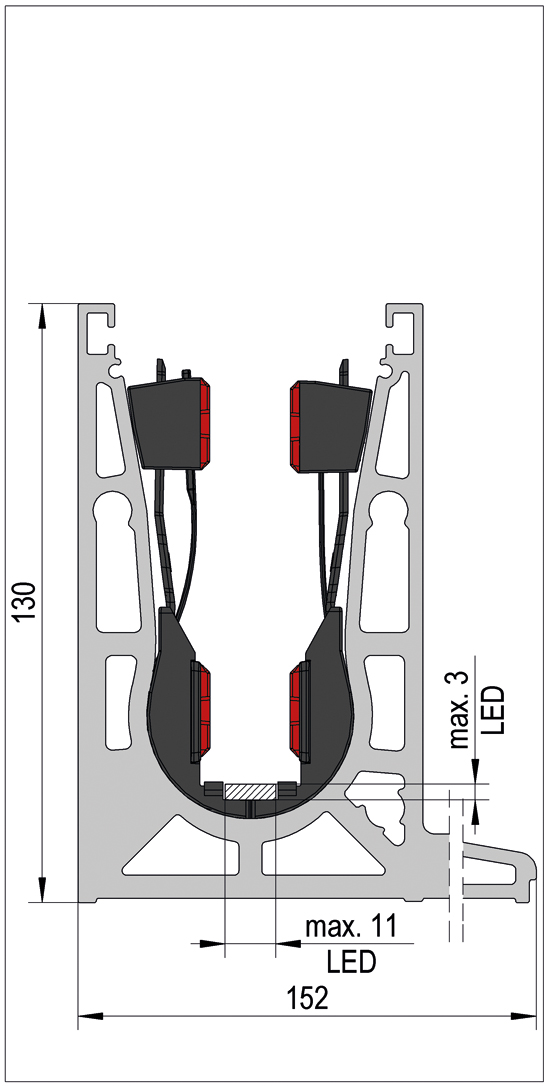

The Floor Profile F made of extruded aluminium is ideally suited for creating a flush finish on the concrete edge. The outer side of the profile can be clad with a cover profile or a building connection profile, as needed. There is a floor connection profile available to enable a smooth transition to the floor structure. For safely fixing the Floor Profile F, a screw distance of only 400 mm is required.

Suitable accessories, such as end caps, cover profiles, rubber spacers, etc. are available.

Important for planning and implementation: For the The General Building Inspection Test Certificate (AbP) and important information on structural properties and drainage, please refer to the “Downloads” section. When planning a glass balustrade system, drainage options must already be considered in the planning phase. In the case of outdoor installations, also wind loads must be taken into account. Our structural properties overview, which you will also find in the “Downloads” section, serves as a basis for planning.

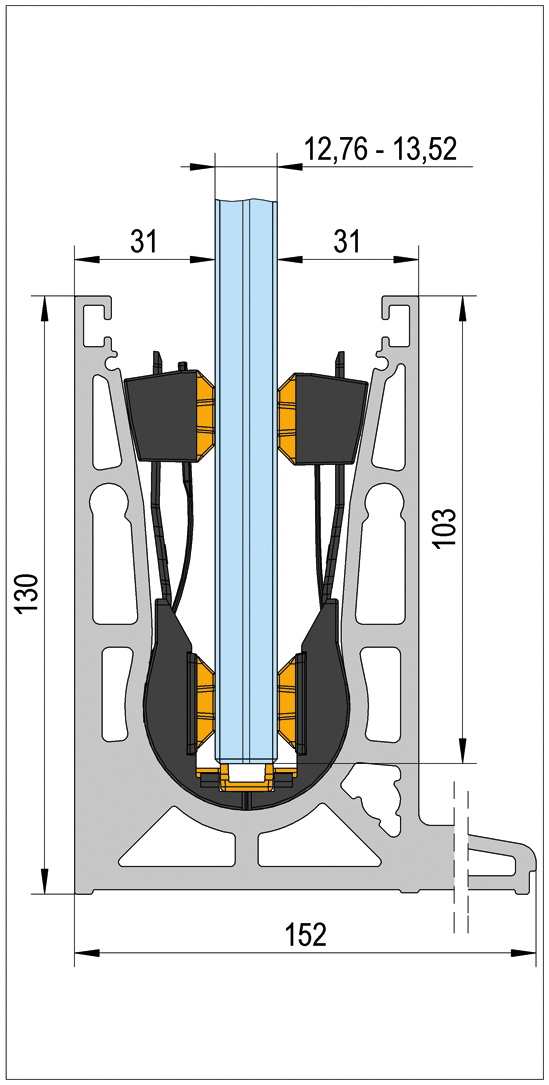

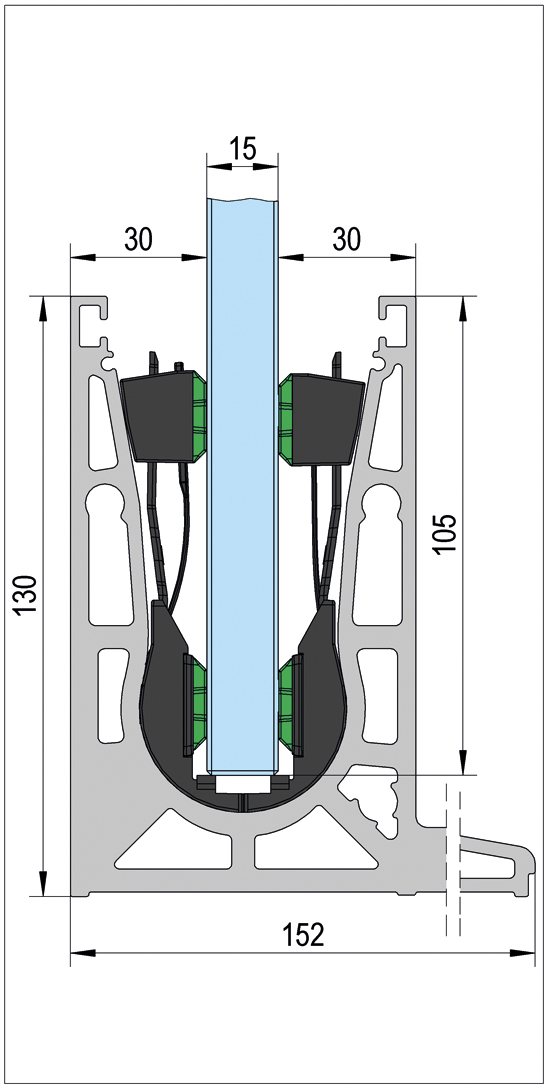

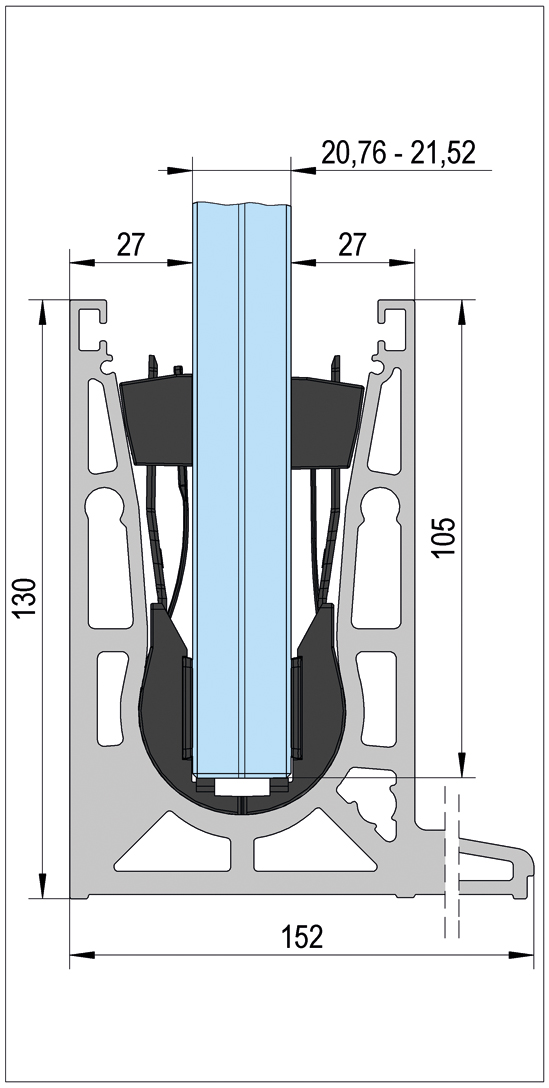

Developed by Bohle engineers, the VetroMount® balustrade system (with General Building Inspection Test Certificate) can be mounted in a few simple steps, saving time and costs. This is made possible by the practical profile fixings and the patented glass bearers. While the profile for top mounting only needs a simple concrete screw every 400 mm for fastening (200 mm for side mounting), the glass is fixed based on the brilliant idea of the cable-tie principle. It makes sure that the glass panes safely lock into place in the profile with the aid of a simple pull-push movement and remain tightly anchored. Insert, adjust, fix – three intuitive steps lead to the perfect balustrade system. In addition, a clever loosening mechanism enables quick disassembly for revision purposes.

- Glass thickness laminated safety glass 12 - 21.52 mm

- max. glass height 1300 mm

- min. glass width 300 mm

- Rail load 1.0 kN (UK: 0,74 kN)

- 103 mm glass insert depth for 12 mm glass thickness, or 105 mm for 15-21 mm glass in the profile

- Tested system – Please take into account the country-specific certification.

- System statics available

- Installation with and without Cover Profile

- Suitable for interior and exterior applications

- For interior applications, we recommend the following screws: Hilti concrete screw HUS3-H 10 x 100 (BO 5211160) or Fischer concrete screw ULTRACUT FBS II 10 x 85

- For exterior applications, we recommend the following screws: Hilti concrete screw HUS-HR 10 x 105 (BO 5211161) or Fischer concrete screw ULTRACUT FBS II A4 US 10 x 85

Additional product information is loading.

Product highlights

- Three intuitive steps towards the perfect balustrade system: insert, adjust, fix.

- Cost-efficient material usage: Low number of fixing points due to the large distance between drill holes (every 400 mm for top mounting)

- Simple concrete screws are sufficient.

- Contrary to the use of standard expansion bolts, the time-consuming cleaning of drill holes together with tightening the bolts and providing proof of the tightening torque is now no longer required. In addition, expansion bolts no longer have to be inserted using a hammer, which can damage the profile.

- Quick disassembly for revision purposes: The entire pane and the glass bearings can be disassembled without any damage.

- Easy integration of a LED illumination in the glass bearers

Accessories

- Mounting sets including glass bearings / rubber seal

- Lateral cover profile

- Upper cover profile

- Cover profile for floor profile F

- End Caps

- Concrete screws

- Rubber spacer for glass panels

- Mounting Aid

- Connecting pins