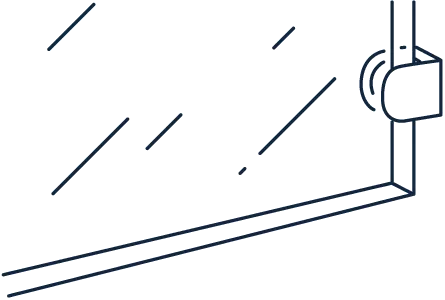

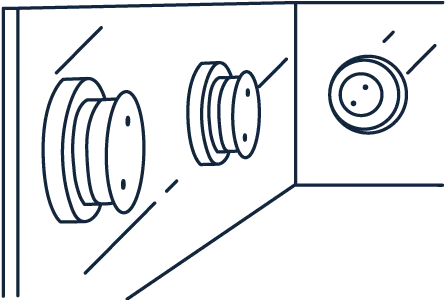

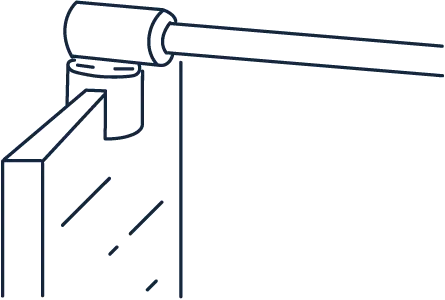

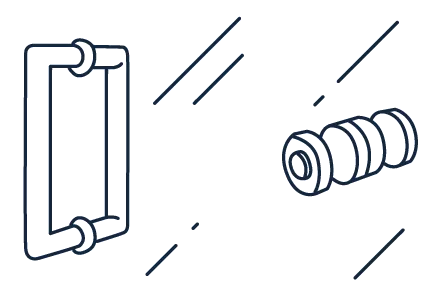

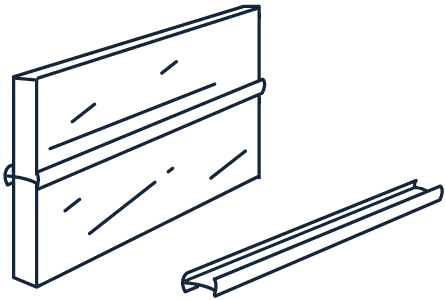

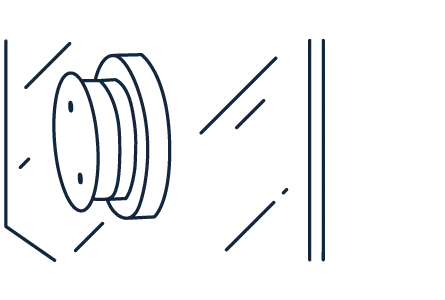

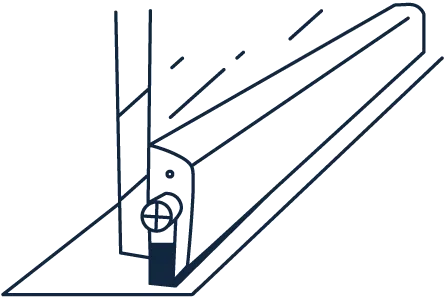

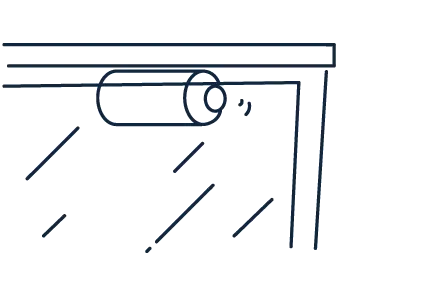

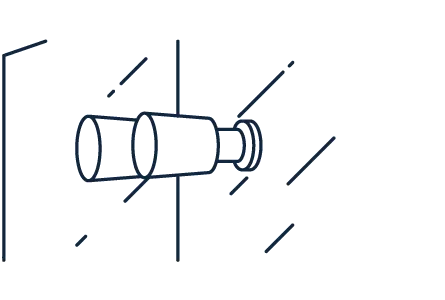

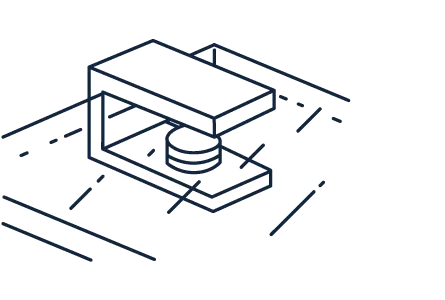

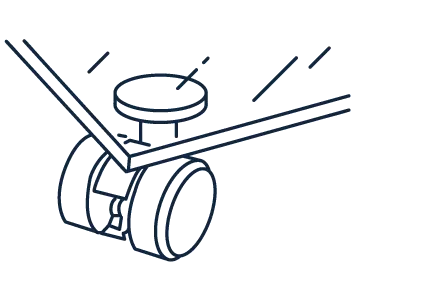

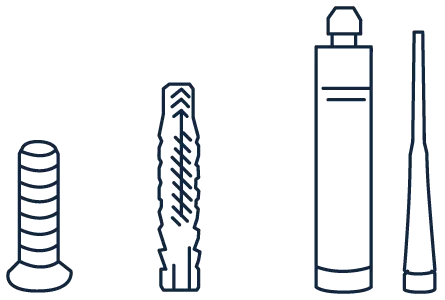

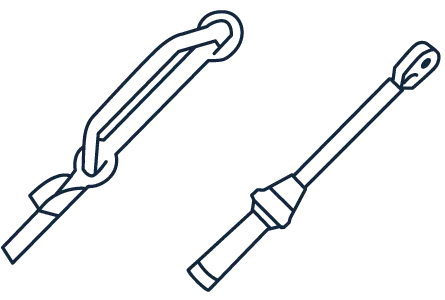

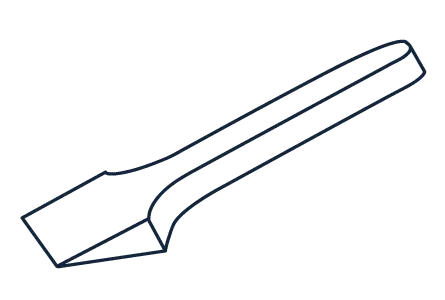

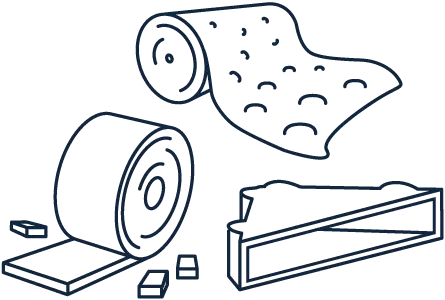

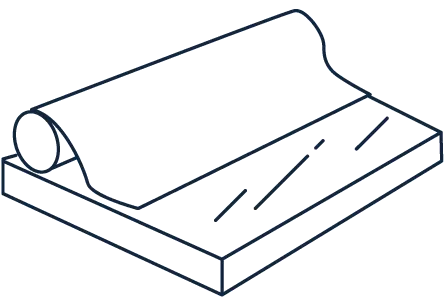

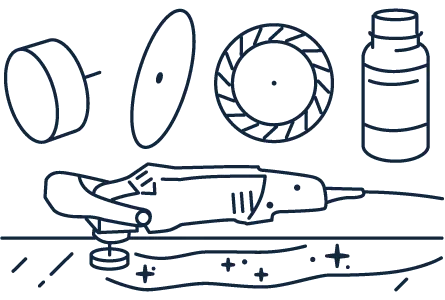

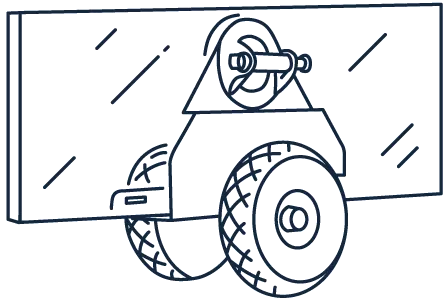

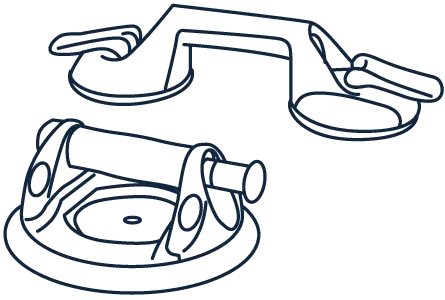

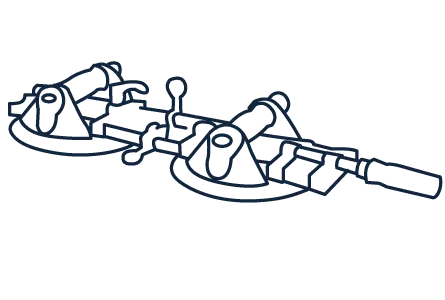

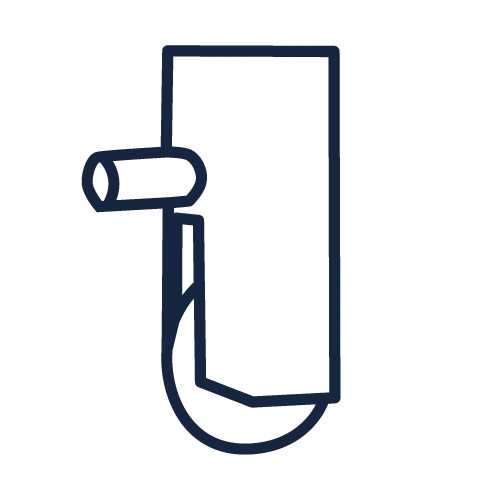

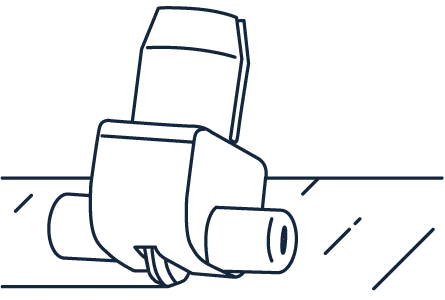

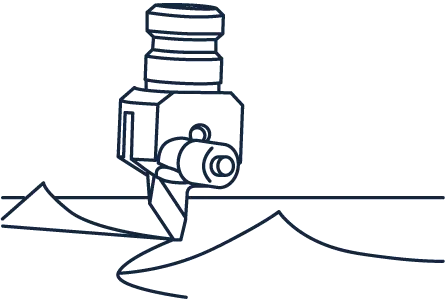

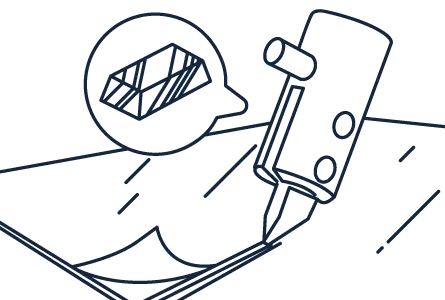

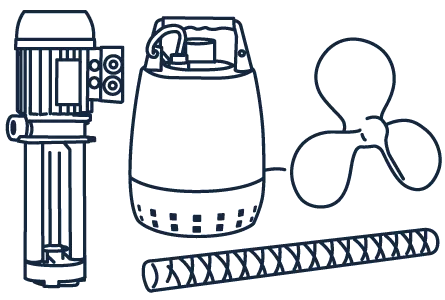

The diamond grinding sleeve KGS® Flexis® Spiral (400 / N 40) is used for grinding the smallest and most difficult to access bores, radii and breakouts. The sleeve is placed on the grinding sleeve holder BO 5007546.

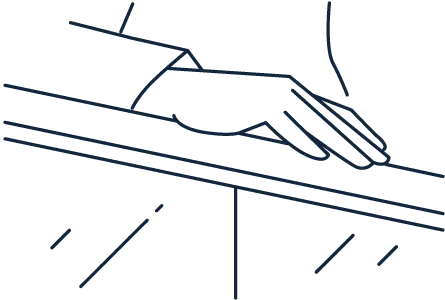

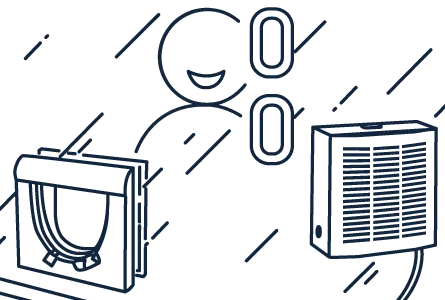

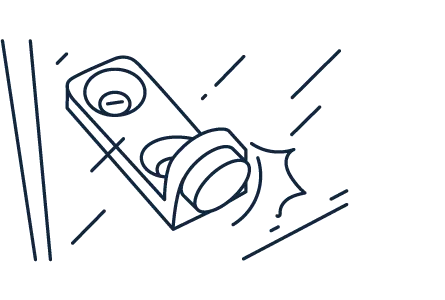

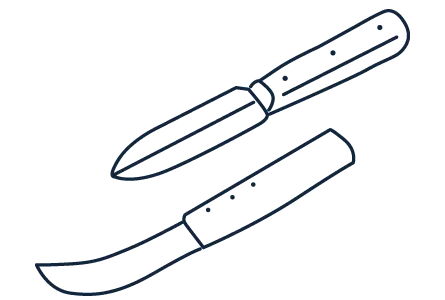

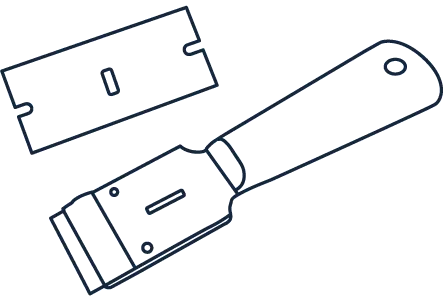

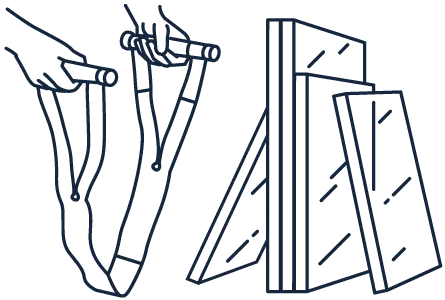

Diamond abrasive sleeves can be used for hard-to-grind materials such as glass, porcelain, rhodium, iridium, titanium, technical ceramics and hard coatings such as tungsten carbide. They are used for finishing corners and edges and cleaning hard-to-reach areas. The abrasive sleeves eliminate unevenness, provide uniformity and an excellent base for fittings. They can be used for shaping, cleaning the edges of drilled holes and for smooth transition of corners. Arts and crafts businesses use them to create sculptures.

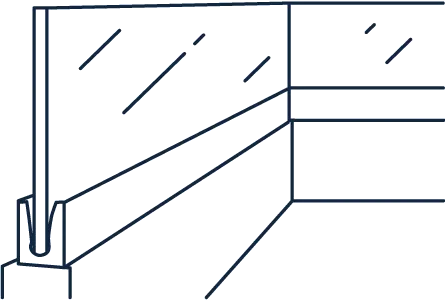

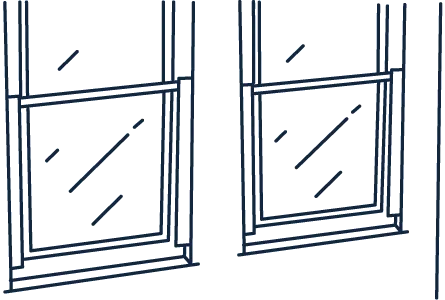

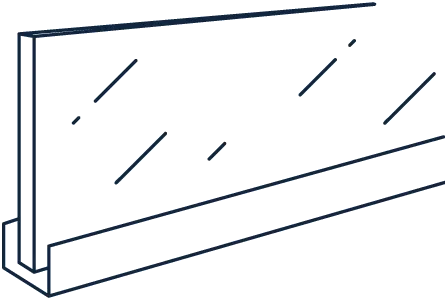

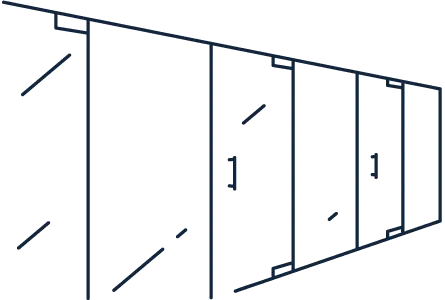

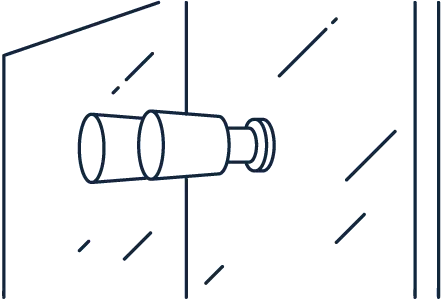

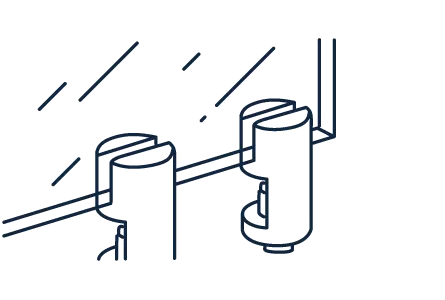

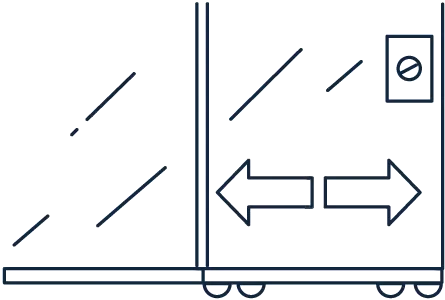

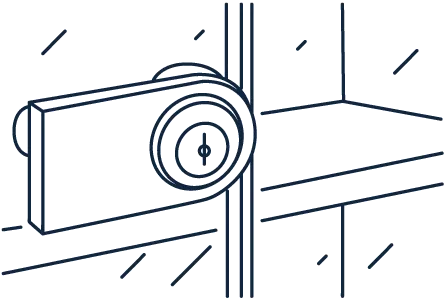

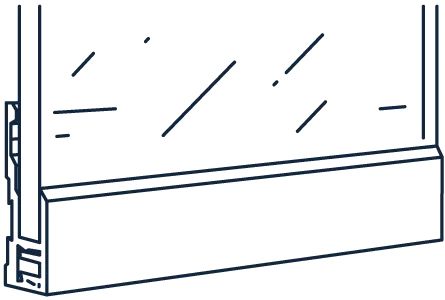

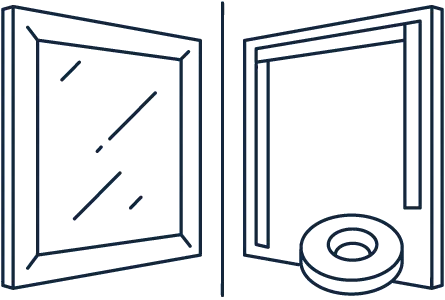

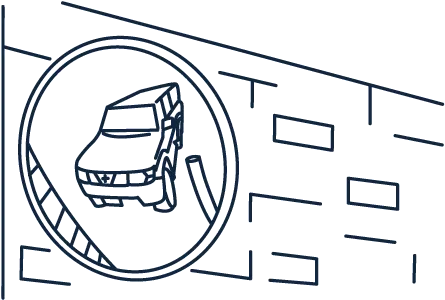

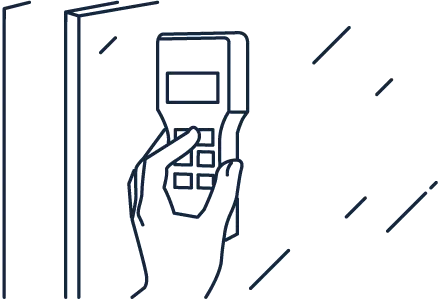

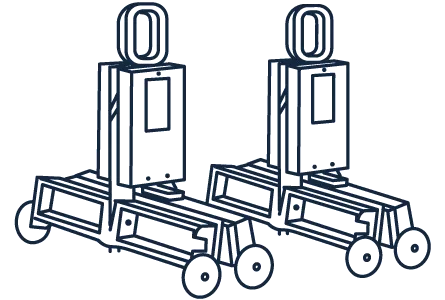

Speciality glass companies, such as glass barrier (swimming pool) companies, use KGS® Flexis® Spiral Diamond Abrasive Sleeves to shape and clean the edges of drilled holes (for locking systems) in glass doors. Grinding sleeves are also used for edge levelling applications that require high accuracy and fine tuning.

Diamond abrasive sleeves are ideal for curved and contoured surfaces that require high attention and accuracy. Also, for polishing corners, edges and cleaning hard-to-reach areas, such as pre-formed holes in sanitary ceramics.

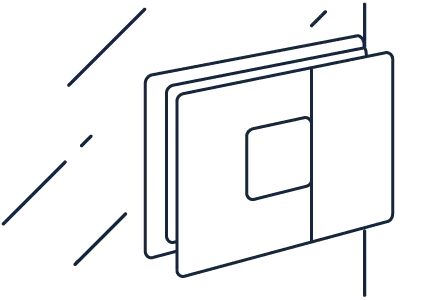

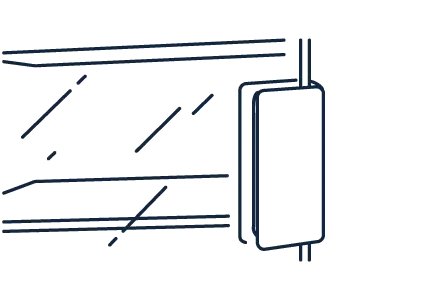

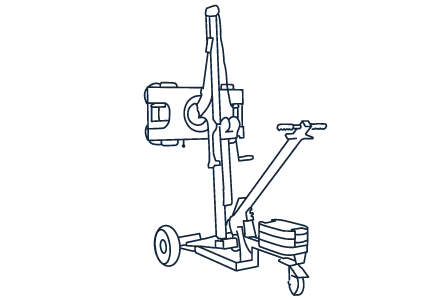

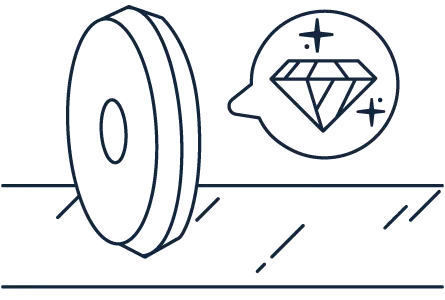

KGS® Flexis® Spiral Diamond Abrasive Sleeves have a reinforced backing that allows high speeds of up to 45 m/s and ensures excellent surface finish. The optimum speed depends on the material to be ground. Slower speeds may prove beneficial for finer grits.

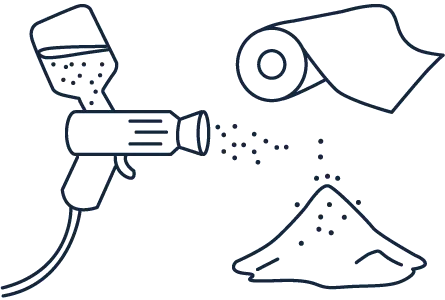

Diamond abrasive sleeves can also be used for overspray removal to quickly remove excess coatings.

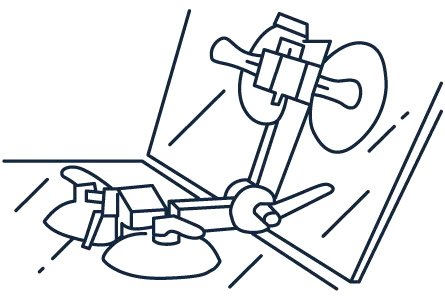

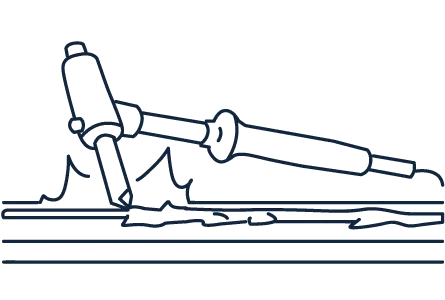

Application note:

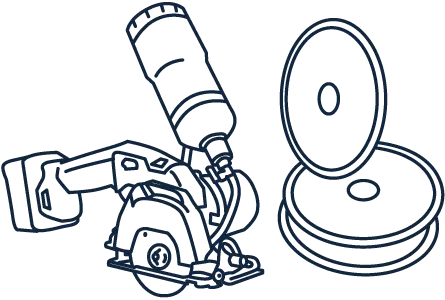

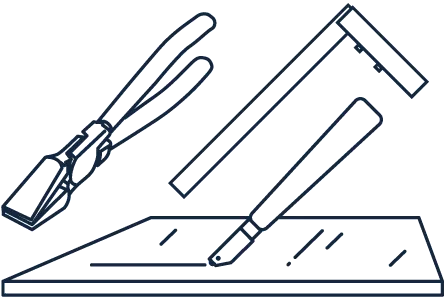

For grinding

Recommended speed: max. 45 m/s