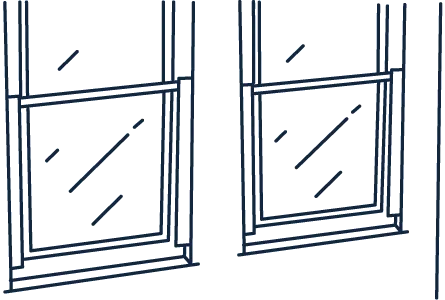

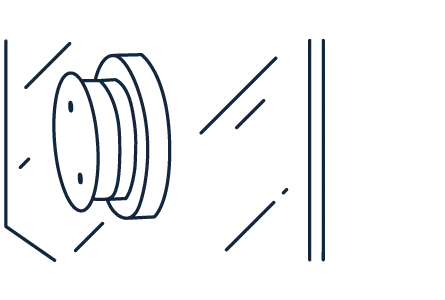

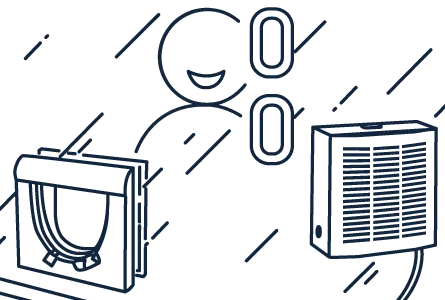

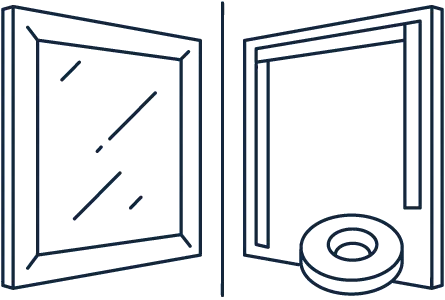

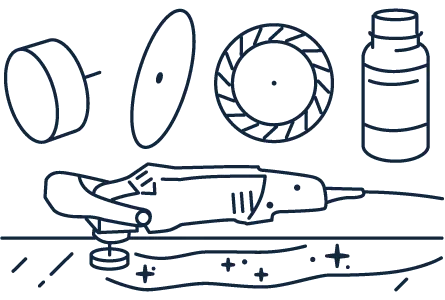

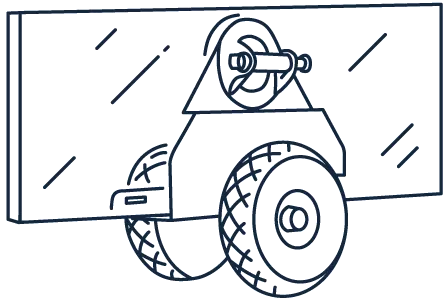

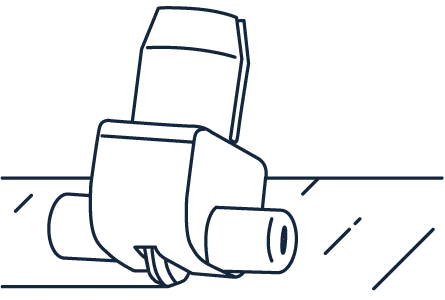

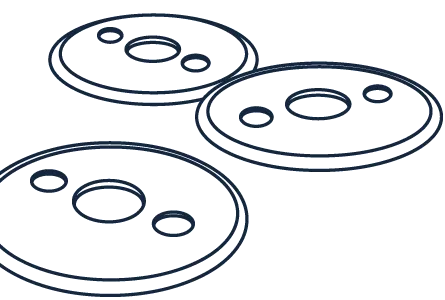

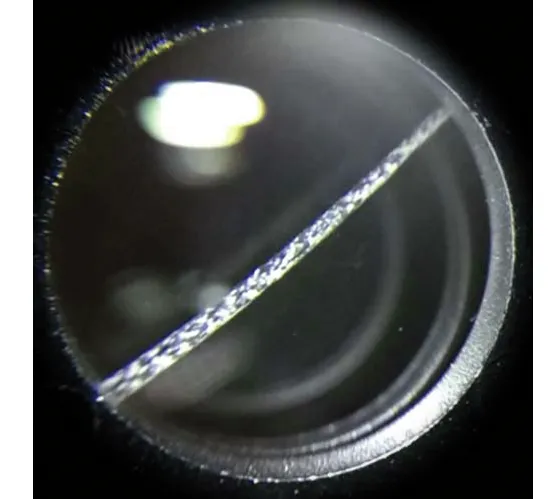

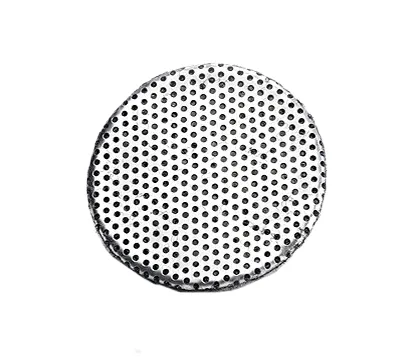

The polishing disc is suitable in combination with the Scratch Away® scratch removal system for removing light scratches, stains as well as acid spots from flat glass, insulating glass, car glass, etc.

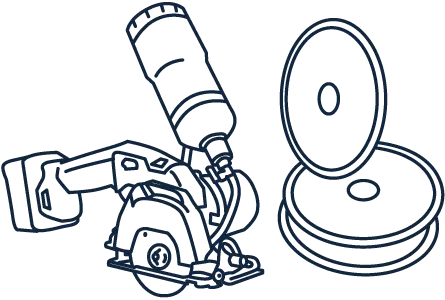

The Scratch Away® polishing disc removes scratches on all types of glass in a single operation.

Efficient and effective

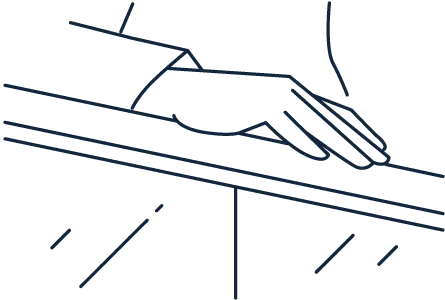

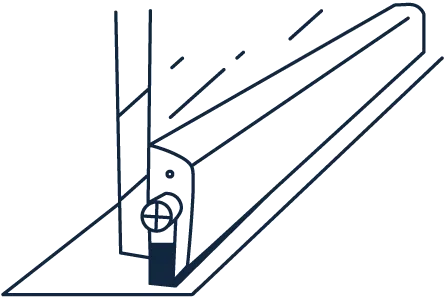

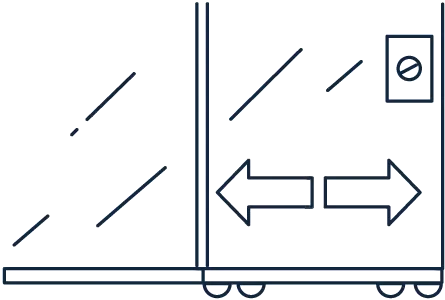

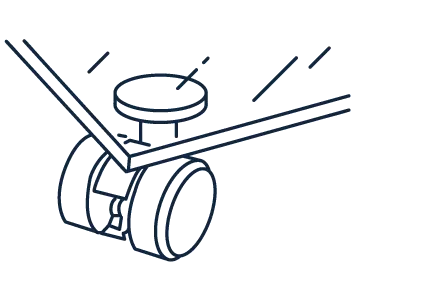

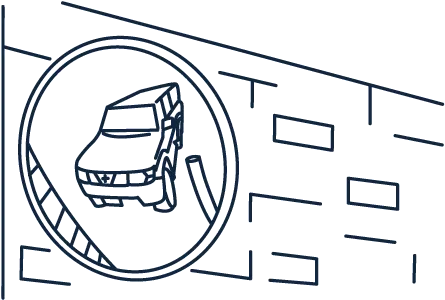

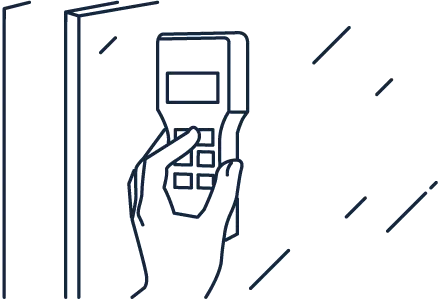

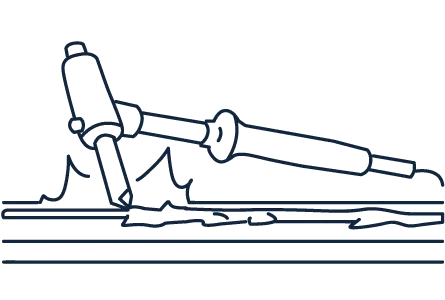

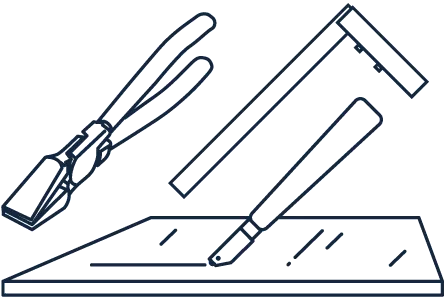

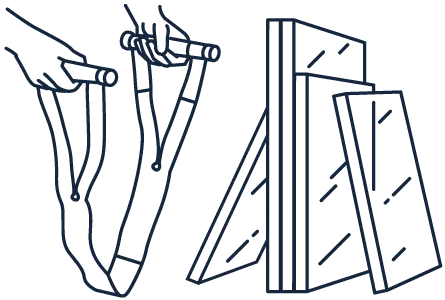

With the Scratch Away® glass polishing disc, all it takes is a little pressure when polishing in a horizontal and vertical position (with the window installed). Thanks to the handy size, the low speed and the splash-free operation, polishing is now efficient and effective in any workshop or on site. It also reduces the risk of causing additional damage to a pane of glass, which could lead to further delays in delivery.

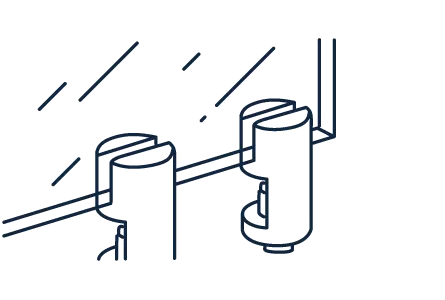

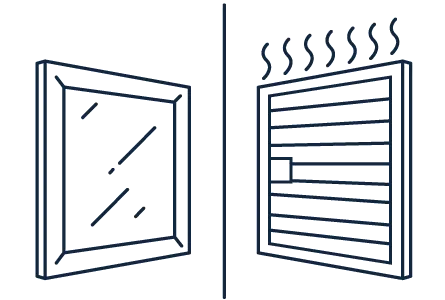

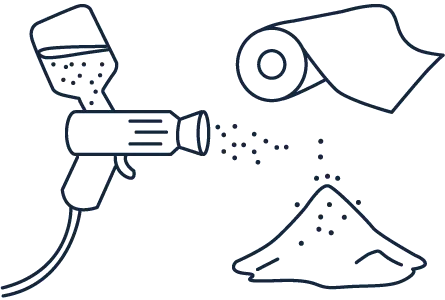

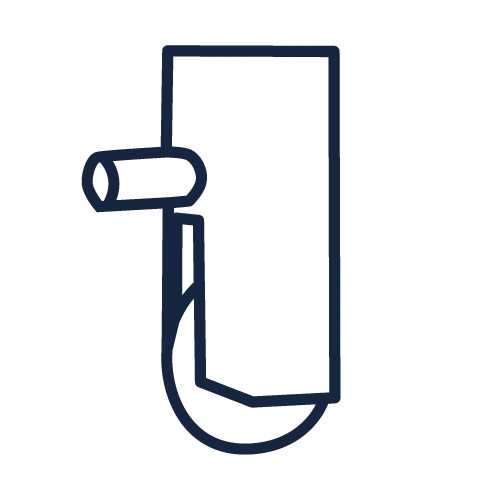

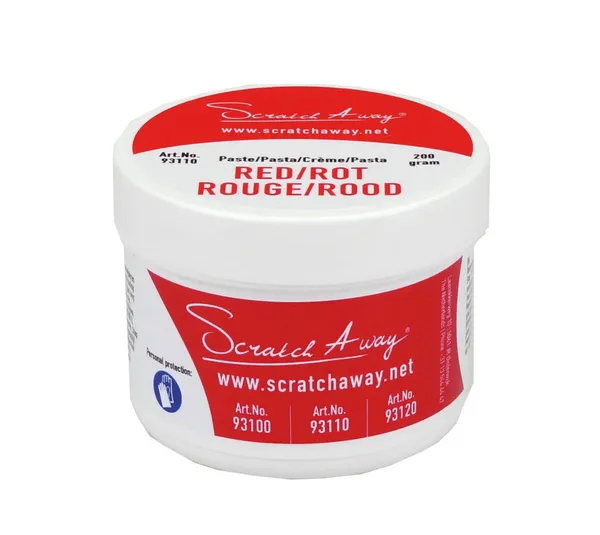

Polishing paste sprays but foam does not

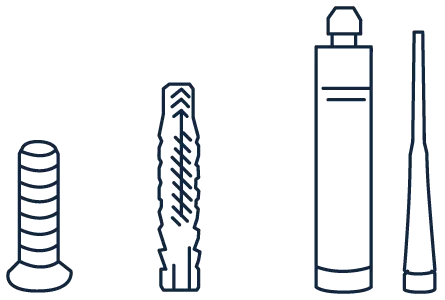

The polishing foam, which comes out of the polishing disc at the correct temperature of 65° C/149° F, remains at the respective damaged spot. The foam therefore does not splash around due to the rotary movement and its own weight - as is the case with conventional polishing paste.

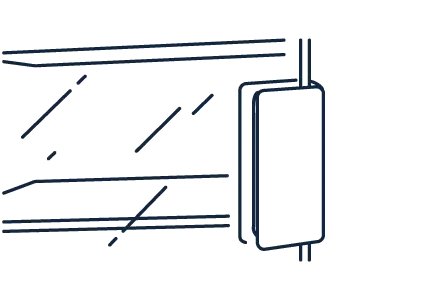

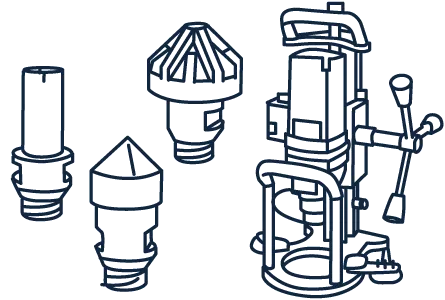

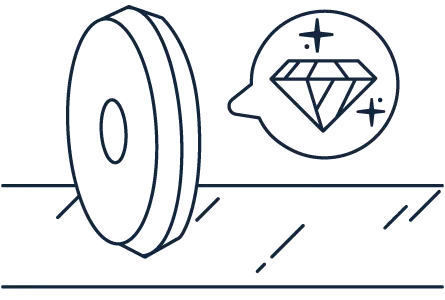

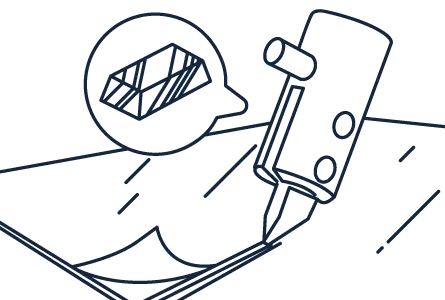

The hardness is crystal clear

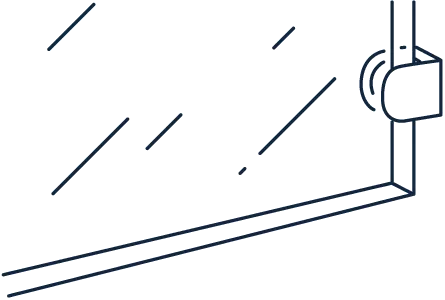

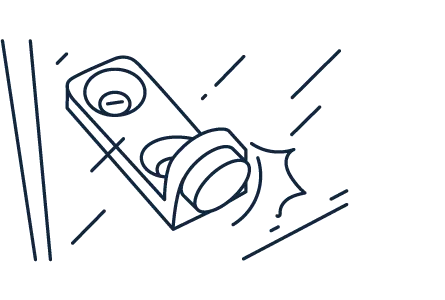

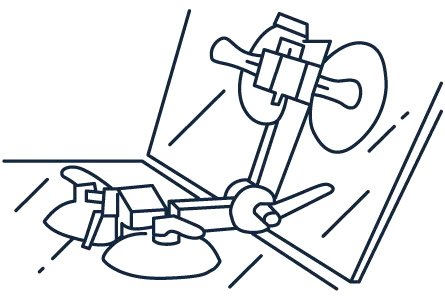

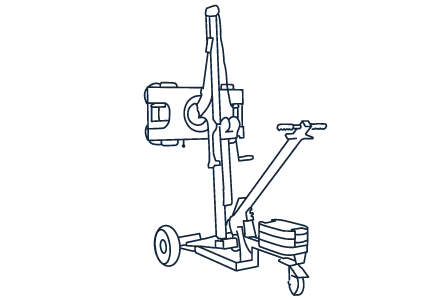

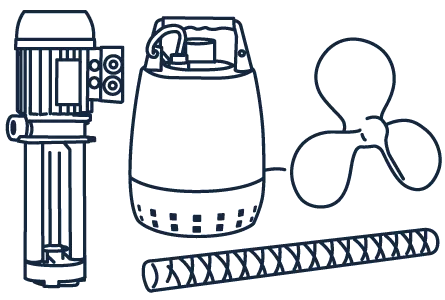

Since glass is a particularly hard material, the pressure that a user has to apply to the polishing device plays a decisive role. Thus, for processing a material such as glass, one pressure per cm² is sufficient; in this respect, the diameter of a polishing disc is decisive. The larger the disc, the more pressure a user has to apply when polishing a scratch for the same pressure per cm².

The Scratch Away® glass polishing wheel can remove +/- 23 scratches with a length of 50 mm. The preferred speed of the machine for polishing the glass is 3.8 almost 4. The final speed at which the glass polishing wheel rotates on the glass should be +/- 65 rpm to achieve a temperature in the glass of 65° C/149° F. The glass should be polished at the same speed as the polishing disc. You can achieve this by applying about 2.5 to 3 kilos of pressure to the top of the machine and spraying a small amount of water.