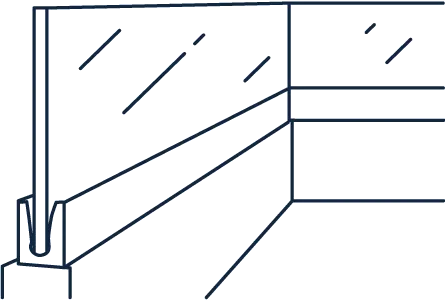

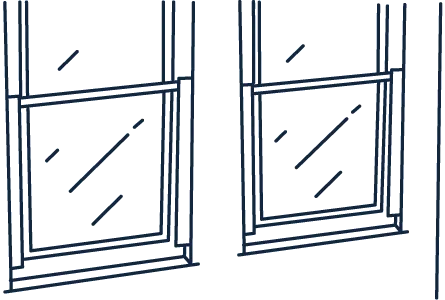

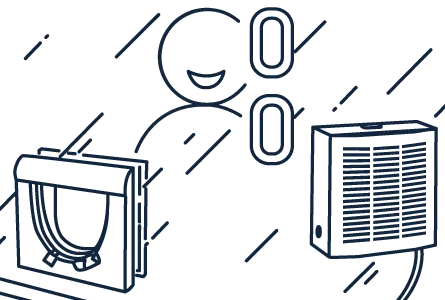

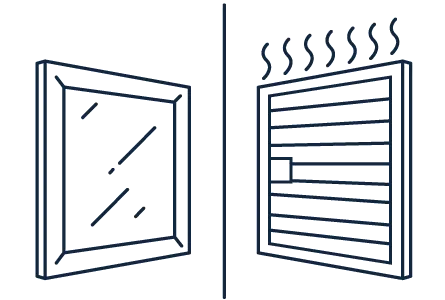

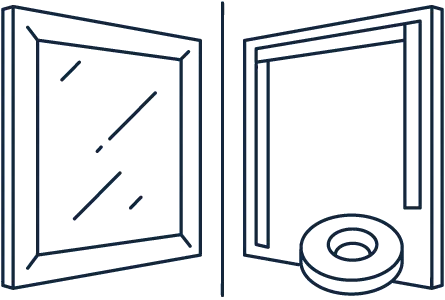

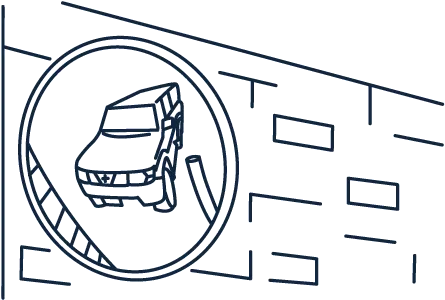

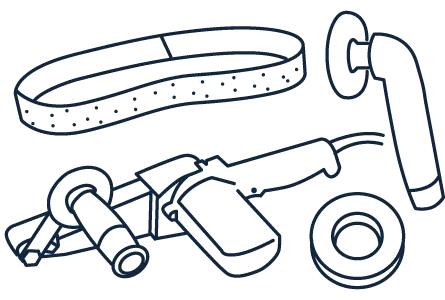

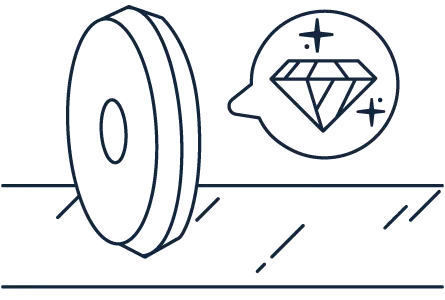

The Pyrosil® process is a special flame pre-treatment for glass and metal surfaces. It is used for bonds that are exposed to high humidity (e.g. bathroom, shower). In addition, the process can be used to improve adhesion on difficult surfaces.

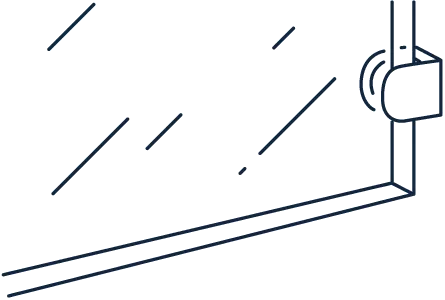

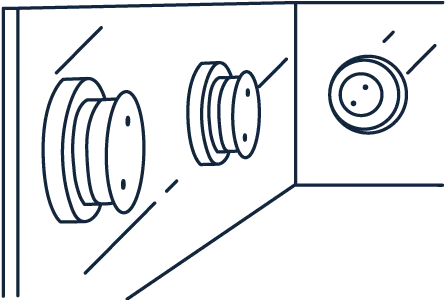

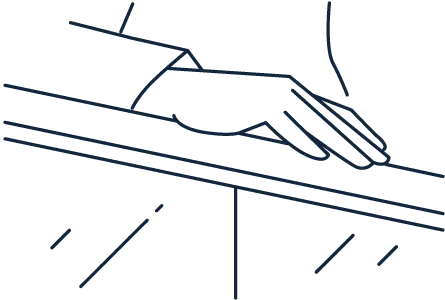

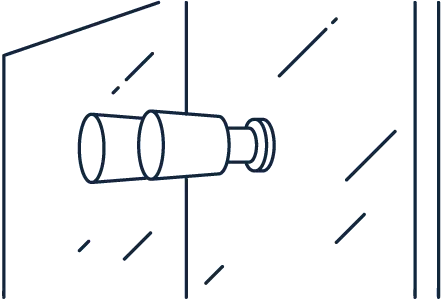

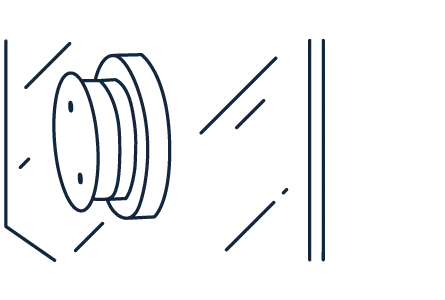

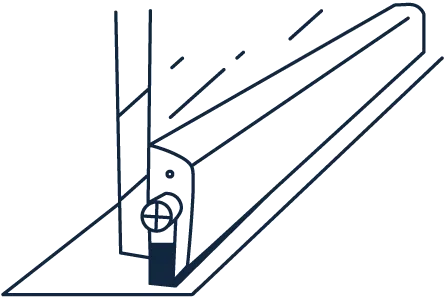

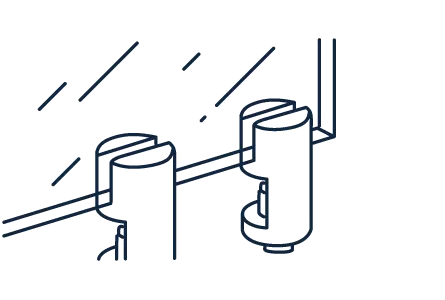

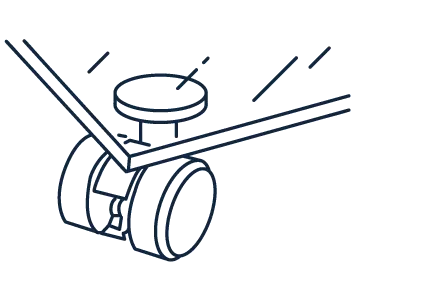

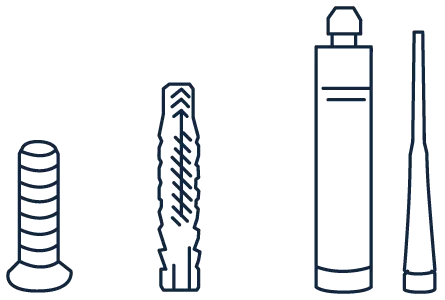

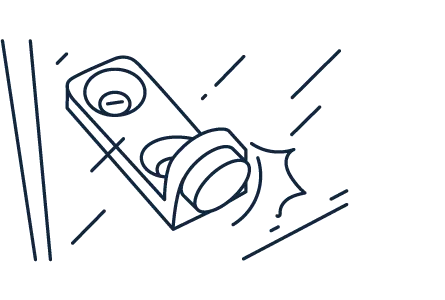

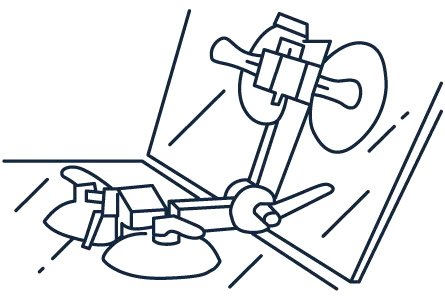

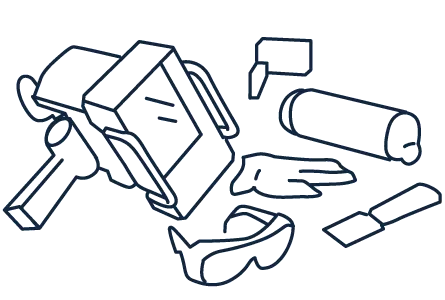

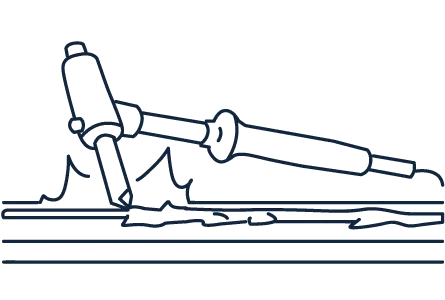

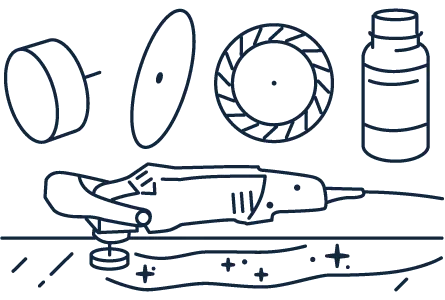

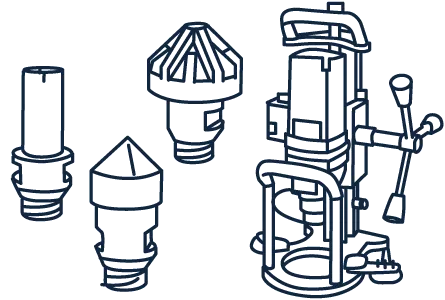

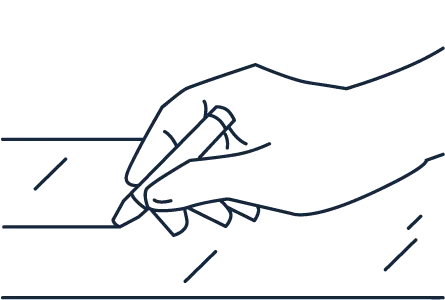

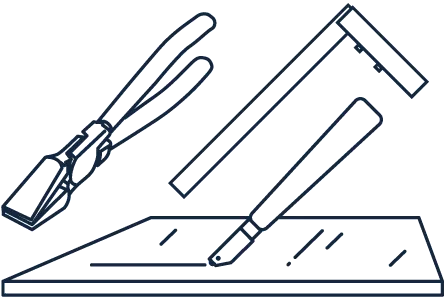

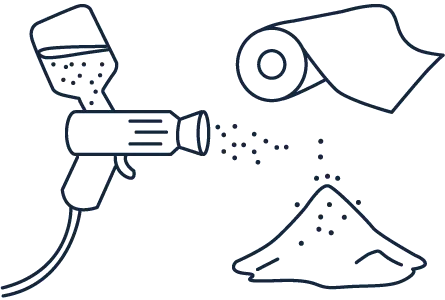

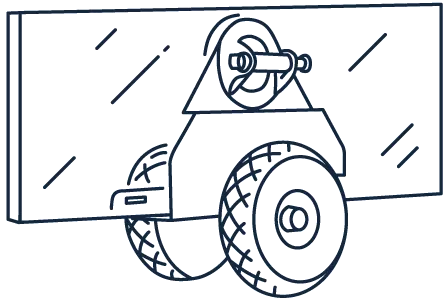

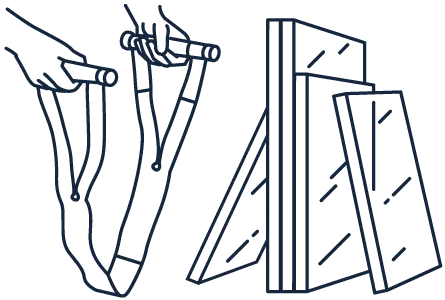

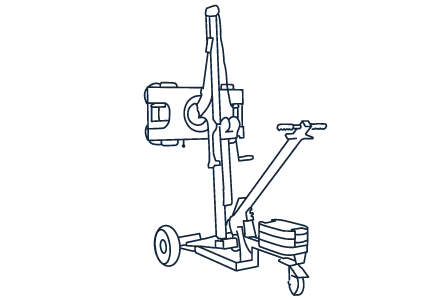

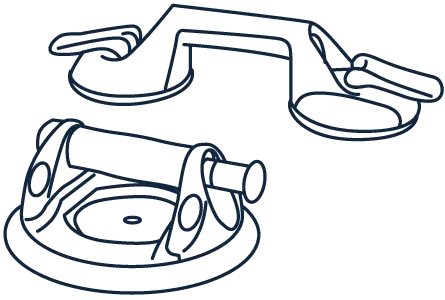

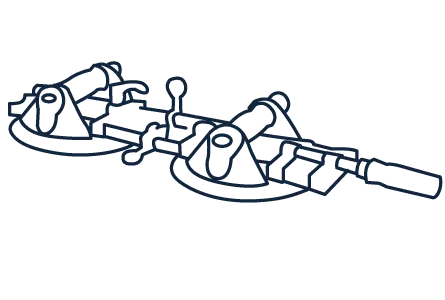

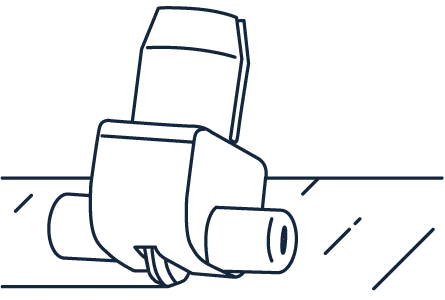

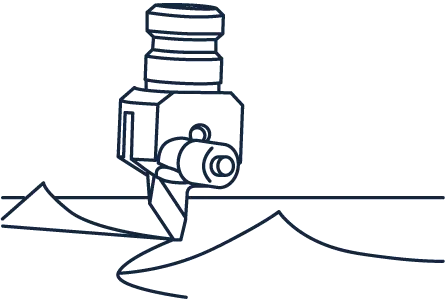

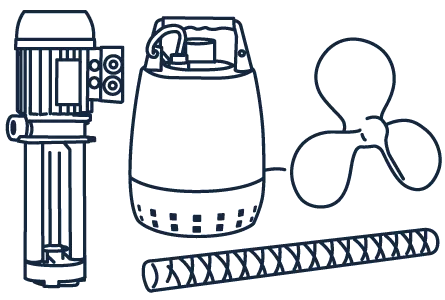

Pyrosil® gas contains a special silicate. The burner flame creates a silicate sinter, which is applied by fanning the surfaces. The Pyrosil® primer is then applied. This is adapted to UV adhesives and forms a chemical bond with them. A bond made with this method is protected from moisture infiltration in the long term. It no longer needs to be additionally sealed in the shower area, for example. The Pyrosil® process achieves the greatest possible adhesion of UV adhesives to glass and metal surfaces. It is therefore also used for demanding and heavily loaded bonds or for bonding difficult surfaces (hydrophobic coated glass, aluminium, chrome, nickel, etc.). Pyrosil® gas and Pyrosil® primer are also available separately. The burner can be refilled until wear and tear means that a clean burner flame can no longer be produced.

Application note:

Observe the safety data sheet, the processing instructions and the relevant technical guidelines and standards. The burner is supplied unfilled.