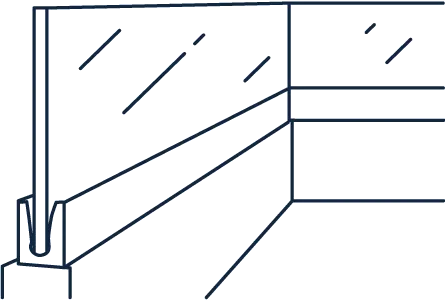

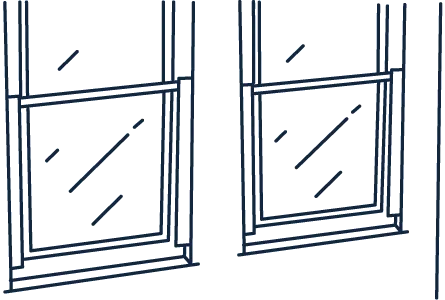

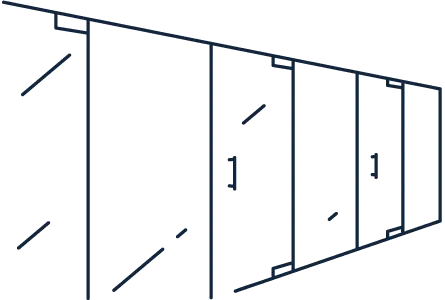

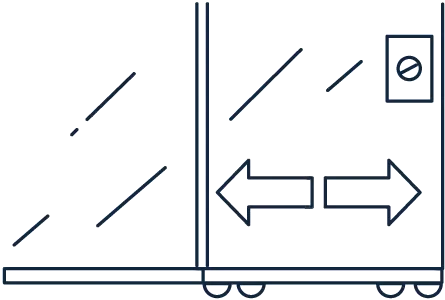

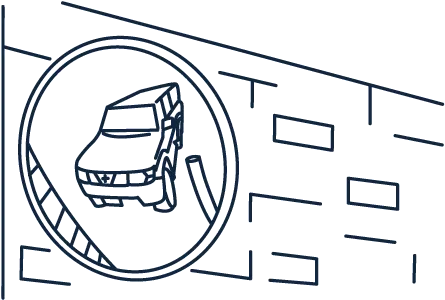

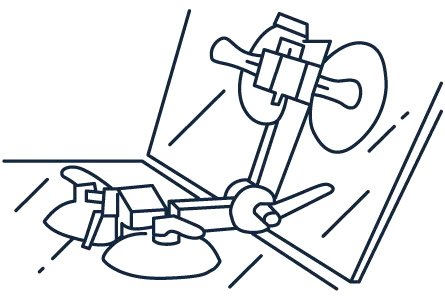

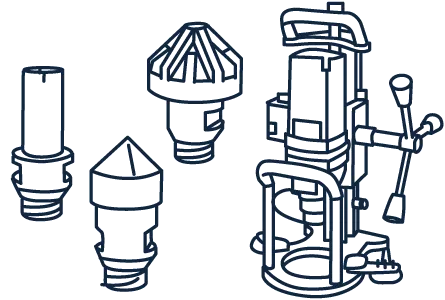

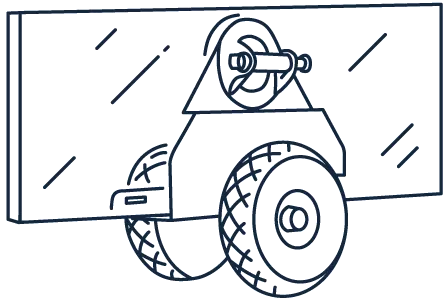

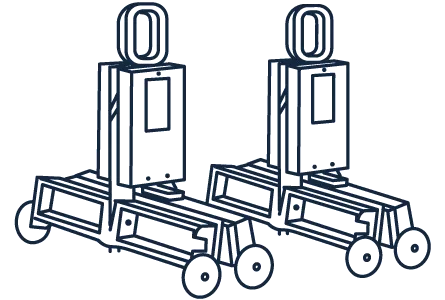

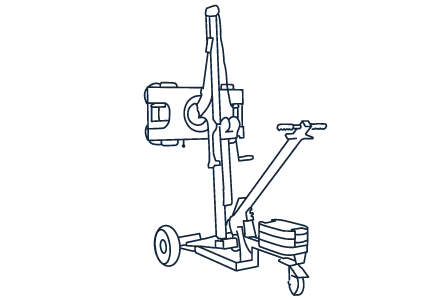

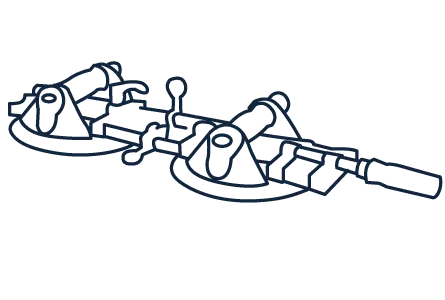

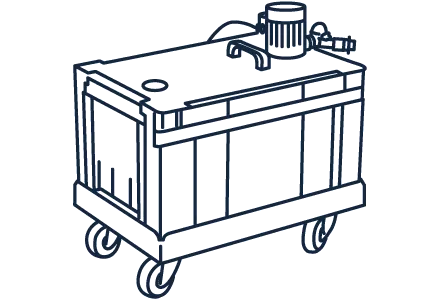

The Bohle Sedimentor 2.4 is used for automatic or semi-automatic grinding sludge cleaning for grinding and drilling machines, edge grinding machines up to approx. 16 spindles and bevelling machines.

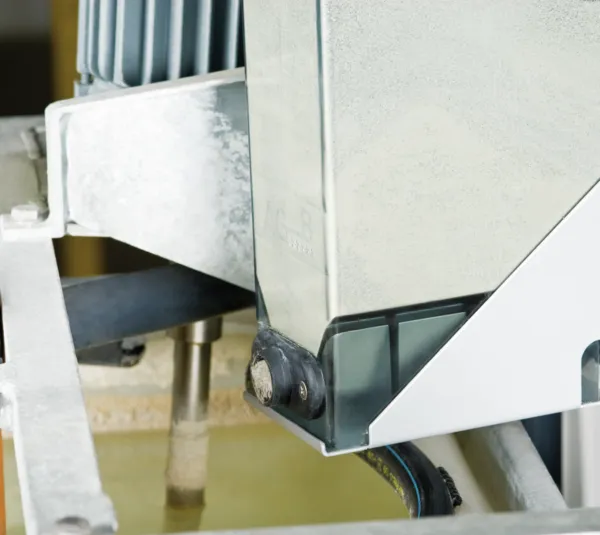

Coarse particles are separated in the flow and fine components are separated with flocculation and filtration. When using a common collecting tank, the process water of several glass processing machines can also be treated.

Why a Sedimentor?

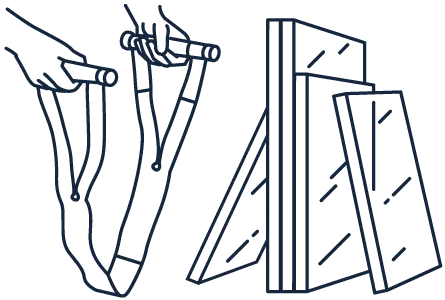

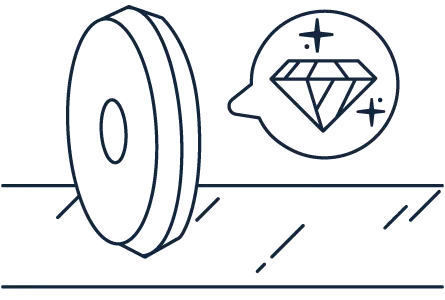

When glass is processed by machine, glass dust is produced which contaminates the process water and makes regular cleaning necessary. Disposal of the dirty water into the sewage system is not permitted. Long-term use of the process water from glass processing machines not only protects the environment, but also your wallet. Sedimentor process water treatment systems from Bohle help to achieve this. This greatly reduces the time-consuming cleaning of the machine clarification system. Further advantages of the clean process water: longer tool life and significantly improved processing quality of the glass, or a higher throughput per hour as well as a stable pH value of the process water, if cooling lubricant is used.

A Bohle water treatment system pays for itself after a short time through increased productivity and cost savings:

Increased productivity:

- Longer operating time due to the elimination of regular machine cleaning

- Higher output due to the increase in grinding speed with the same edge quality

- Less effort required for the subsequent cleaning of the ground glass

Cost savings:

- Significant minimisation of fresh water and waste water costs

- Less tool wear

- Significantly lower energy costs (compared to centrifuges)

- Enormous reduction in maintenance costs (compared to centrifuges)

Other possible advantages:

- Prevention of machine corrosion

- Compliance with (future) regulatory requirements

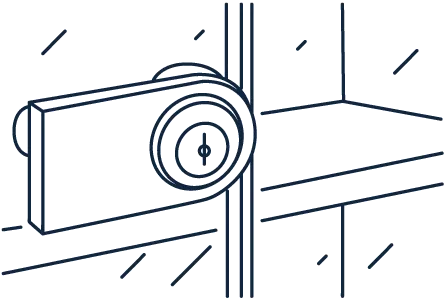

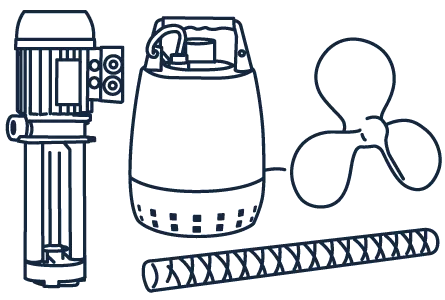

- Simple and easy-to-maintain system technology