Silberschnitt® cutting fluids

The perfect complement for optimum glass cutting

Washable or evaporating

Silberschnitt® cutting fluids are available for all common applications: from easily washable to completely evaporating cutting fluids. Choose from three evaporation levels or two wash-off variants to find the optimal solution for your needs.

Silberschnitt® cutting fluids are synthetically produced, high-purity lubricants which, in contrast to polluted mineral oils, in addition to improved chemical and mechanical properties, do not affect the health of the user in case of skin contact or inhalation.

It is not only the potential effects on human health that make mineral oils such as petroleum or paraffin unsuitable lubricants for glass cutting. A sometimes highly fluctuating raw material quality and a lack of control of the raw material quality lead to inconsistent results in production. Silberschnitt® cutting fluids enable excellent product quality, ensure reproducible results and a stable production process.

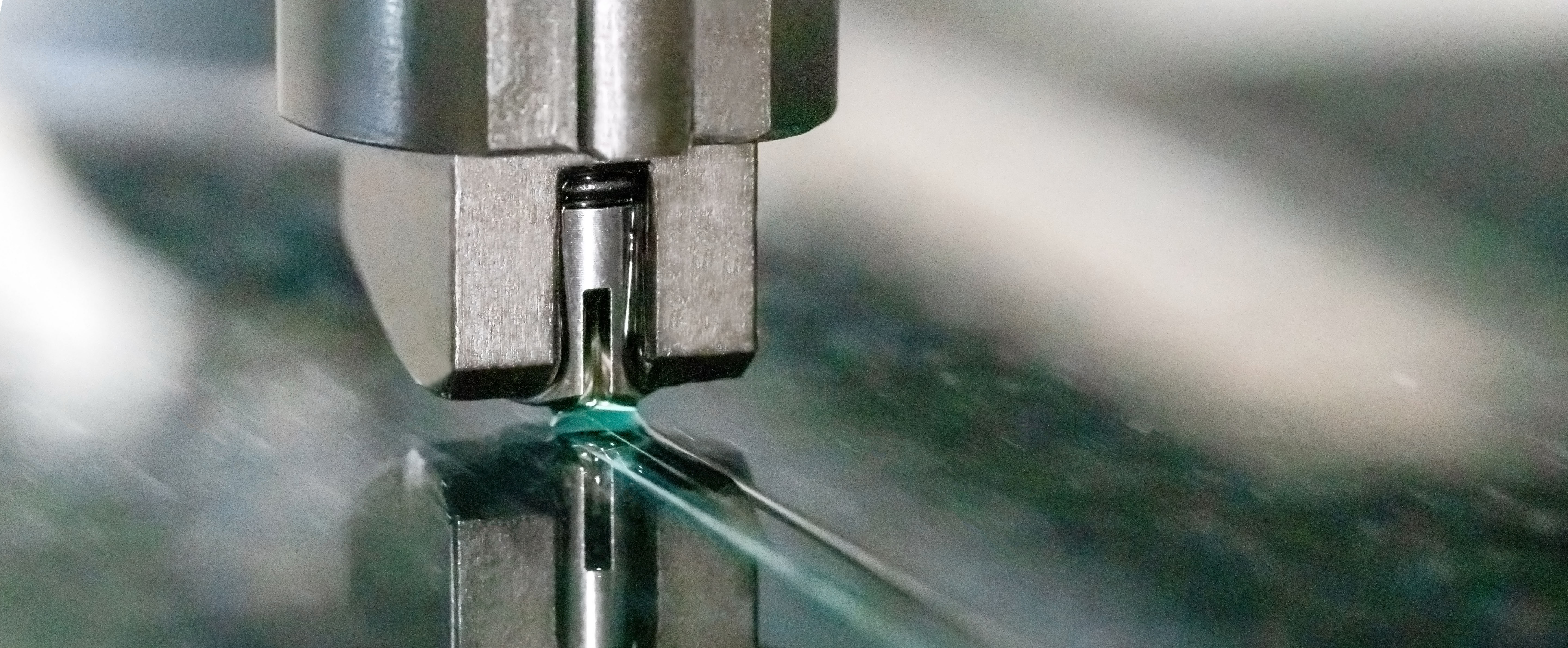

- Cutting fluids lubricate the cutting wheel, minimising friction and thus enabling longer tool life.

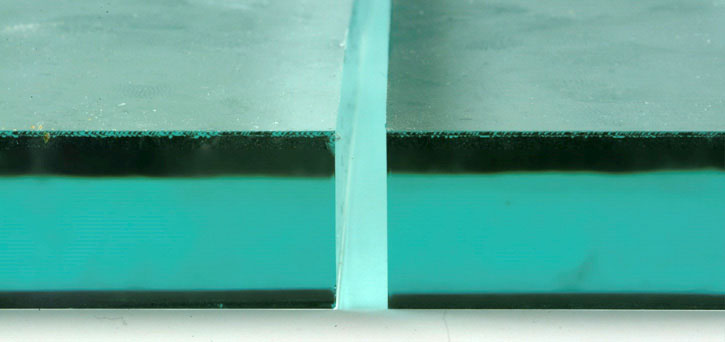

- A reduction in cutting force results in less damage to the glass surface, leading to less chipping and better edge quality.

- The binding of the finest glass particles avoids consequential damage in the downstream process steps.

Quality cutting fluid

The way to first-class edge quality is very simple: rely on modern, synthetic cutting fluids! Compared to traditional lubricants such as petroleum or paraffin, they offer several advantages: a unique lubricating effect, an audibly softer break and the binding of glass dust to reduce crumb formation.

Since both manufacturing processes and environmental conditions are different for each manufacturer, the cutting fluid must also be adapted to the respective conditions.

Important selection criteria are, for example, the glass thickness, the surface temperature or the application system. We will be happy to advise you!